At Winnellie Valve and Process, we supply quality Subsea Valves in a range of design types to suit all applications. If you’re looking to buy Subsea Valves in Australia, you need look no further than our extensive product range. If you’re unsure about which type of Subsea Valves you need for your application, or would simply like more information and guidance, Winnellie Valve and Process are only too happy to chat through your options with you.

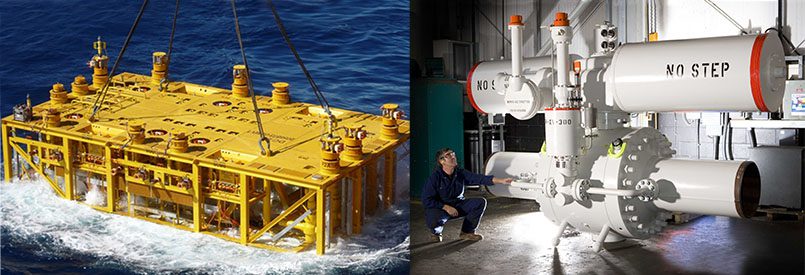

Subsea valves are highly engineered valves tailored to specific requirements for various subsea-related projects. They are used to isolate or control the flow of media through an undersea pipeline (submarine pipeline) or other associated applications. They perform an integral part of subsea flow infrastructure in both shallow and deep water.

Subsea Valves (as the name suggests) are used in underwater environments, so considerations for Subsea Valves over regular valves are that they must be waterproof, be able to handle an increased ambient pressure load and need to be constructed using materials that are able to handle long-term corrosion effects from high salt content seawater.

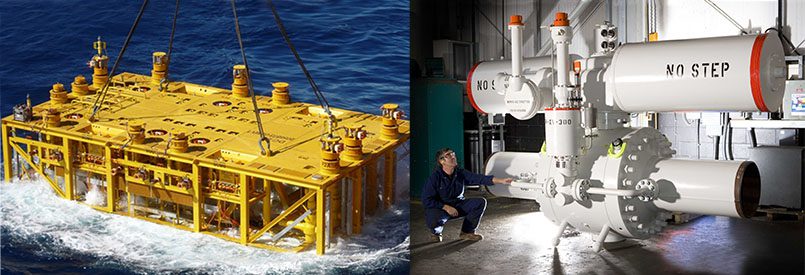

Subsea Valves are able to be manually geared or actuated with hydraulic actuators. There are three basic groups of valves on a subsea system: choke, check and on-off. Choke Valves are valves used to reduce pressure or restrict flow from a well, while on-off valves isolate the flow of media and are specifically designed to be either left all the way open or all the way closed. Check Valves prevent backward flow of media.

Subsea Gate Valves

These valves can be either slab or double expanding, and are the most common types of valves used subsea environments. They are usually hydraulically actuated and sometimes with the assistance of an ROV (remotely operated vehicle) for operation. Subsea Gate Valves tend to be heavier and are constructed with overlays of corrosion-resistant alloys.

Subsea Ball Valves

These valves can be trunnion or floating ball designs and have an advantage over Gate Valves as they come in a more compact design for when you have weight or space limitations. A Floating Ball Valve, the ball is free to move and the seats are fixed, so when pressure increases the higher the force is pushing the ball against the seat – therefore, the higher the pressure, the better it seals. With a Trunnion Ball Valve, it inverts the roles and the ball stays fixed as the seats move.

It’s always wise to look at what media is flowing through the application before you choose which configuration of type of Subsea Valve you require. Talk to a Valve and Process expert to get the right valve for your application.

Subsea Valves are predominantly used in the oil and gas industries where they are utilised under the sea or ocean and require extra protection for waterproofing and against corrosion.

For more tips on the use, service and maintenance of Subsea Valves, contact a Winnellie Valves expert or sign up for one of our many different valve and process training courses.

It’s always best practice to have a qualified technician install your valves for industrial applications. However, if you want to be able to install a Subsea Valve your self, contact a valve expert to guide you through the process. Winnellie Valves and Process also provide valve training courses for all types of valves.

You can also contact our trainer directly as per below contact details

e: Iain@winnellievalves.com

ph: +61 (0) 417 279 508