At Winnellie Valve and Process, we supply quality Plug Valves in a range of design types to suit all applications. If you’re looking to buy Plug Valves in Australia, you need look no further than our extensive product range. If you’re unsure about which type of Plug Valves you need for your application, or would simply like more information and guidance, Winnellie Valve and Process are only too happy to chat through your options with you.

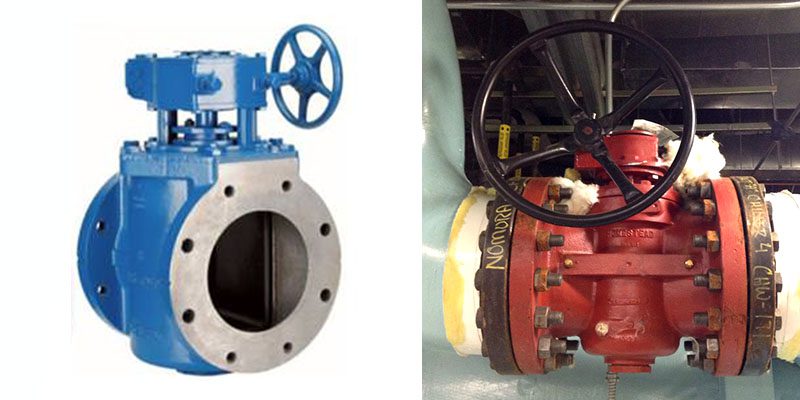

Plug Valves come available in conical or cylindrical shapes and are quarter-turn manual motion valves used to stop or start the flow of fluid. The plug itself is the only element capable of movement.

Plug Valves have hollow passages through the valve body. Their quarter-turn motion will create an alignment between the pipe and the hole,

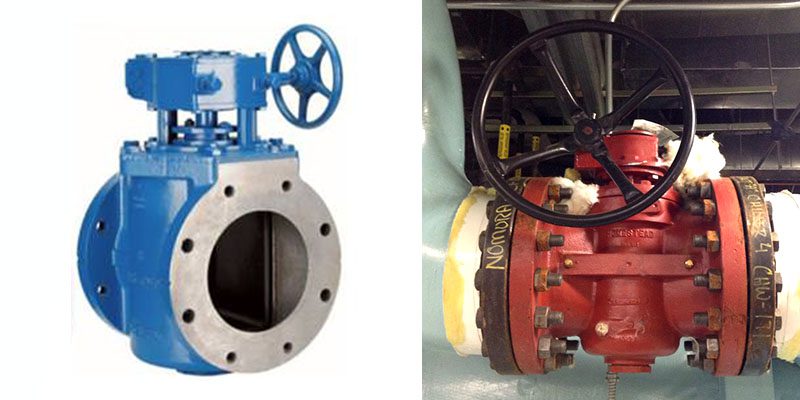

Plug Valves are widely used in hydraulic systems and associated operations. They are an essential component to ensure the efficient running of processes. They are utilised in bubble-tight services as an on-off stop valve. They are used in gaseous and vap our services, natural gas and oil piping systems, abrasive slurry and high-pressure applications.

Gate valves are normally wide open or completely closed. Like gate valves, plug valves are used primarily for non-throttling, on-off service. They require minimum Installation space and utilise a simple and quick “quarter-turn” design.

Although there are many types of Plug Valves to buy in Australia, there are five general categories, each with their own benefits.

Lubricated Plug Valves

These valves use a lubricant that is injected between the plug face and body seat to seal ports and reduce friction. Because they are considered high maintenance, they are more often used in applications that have infrequent operations.

Non-Lubricated Plug Valves

This type of Plug Valve has a sleeve which encapsulates the plug ensuring there are no cavities or dead space. These plug valves are ideal for application where the product may crystallise in the cavity preventing the valves from turning. A similar design to these sleeved plug valves is the lined plug valve which as well as having the sleeve around the plug also has a PTFE liner on the inside of the body which provides a corrosive resistant barrier between media such as acids and the valve body.

Lift-Plug Valves

Lift-plug valves utilise a cone shaped plug that lifts out of the seat prior to rotating 90 degrees and then lowering back into the seat. This means that even though it is a metal-to-metal seal there is no contact between the plug and the seat during operating, eliminating wear and increasing lifespan of the valve.

Eccentric Plug Valves

Eccentric Plug Valves are used for a range of flow control and isolation applications and use a half plug for processes requiring a higher seating force with minimal friction from the open to closed position.

Expanding Plug Valves

These valves are complex and have multiple components that allow the valve to mechanically expand for a true double-block and bleed function in the one valve. A mechanism rotates between the open and closed positions that protects both seals from the path of the flow. Expanding Plug Valves are often used to prevent product contamination between tanks containing different fluids or critical isolation applications.

To buy the right Plug Valve for your application contact one of our valve experts today.

There are a range of specifications to consider when selecting a Plug Valve. Because they can be used in a variety of applications. Points to consider include pressure, temperature, corrosiveness and slurry content.

It’s always best to have a qualified technician install your valves for industrial applications. However if you want to be able to install a Plug Valve yourself, contact a valve expert to guide you through the process. Winnellie Valves and Process also provide valve training courses for all types of valves.

You can also contact our trainer directly as per below contact details

e: Iain@winnellievalves.com

ph: +61 (0) 417 279 508