At Winnellie Valve and Process, we carry an extensive product range of quality Double Block and Bleed Valves in a range of design types to suit all applications. If you’re looking to buy the most comprehensive range of Double Block and Bleed Valves in Australia, you need look no further than our premium collection. If you’re unsure about which type of Double Block and Bleed Valves you need for your application, or would simply like more information and guidance, Winnellie Valve and Process are only too happy to chat through your options with you.

The primary purpose of a Double Block and Bleed Valve is to ensure positive isolation downstream to protect equipment and/or maintenance personnel performing tasks downstream of the valve. Under certain conditions double block and bleed systems are needed to prevent product contamination or where it is necessary to remove essential equipment from service for cleaning or repairs while the unit continues in operation.

There are two official definitions of Double Block and Bleed Valves:

API 6D defines it as a single valve with two seating surfaces that, in the closed position, provides a seal against pressure from both ends of the valve with a means of venting/bleeding the cavity between the seating surfaces. When just one side is under pressure, this valve does not have positive double isolation.

OSHA defines a Double Block and Bleed Valve as the closure of a line, duct, or pipe by closing and locking or tagging two inline valves and by opening and locking or tagging a drain or vent valve in the line between the two closed valves. If you require training on how to operate and maintain your valves, have a look at Winnellie Valve and Process training options today.

Double Block and Bleed Valves in Australia are used where critical sealing is necessary to make sure no leakage occurs. Both valves can operate in various applications and industries, such as the oil and gas industry, petrochemical, transmission and storage, industrial processes for natural gas, main-line and multi-purpose valves in liquid pipelines, and transmission lines of refined materials.

The demand for metre calibration is another application where the Double Block and Bleed Valve is used. Each valve closed to the metering device must be tightly sealed. Even a minor leak causes errors in metre calibration and the inaccurate metre factor remains until the next proven procedure and hence this can cost large sums of money in a product that is not accounted for. Choosing the right Double Block and Bleed Valve to buy for your application is important. Contact one of our friendly team members for more information on which type of valve you require.

Double Block and Bleed Valves are classified in three main structure types:

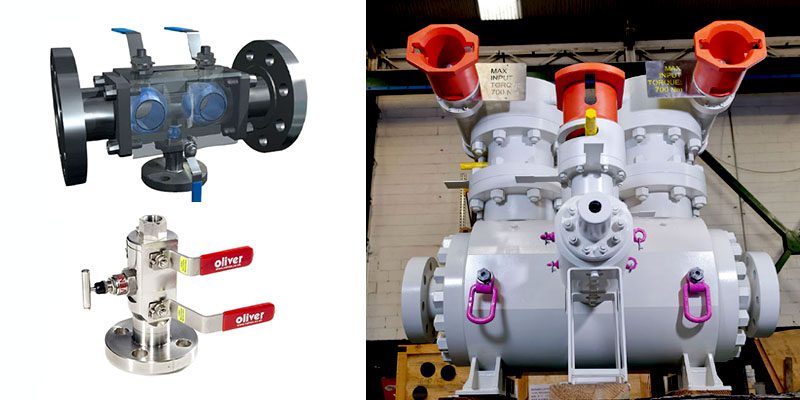

Modular or Split Body Type DBB Valve – The main feature of this design is that it has two balls in one valve to ensure greater safety. A drain needle valve is located between the two balls on the Double Block and Bleed valve. This allows the valve to be drained and the pressure to be reset to zero. Instrumentation and piping all benefit from the modular form, three-piece body construction. Instrumentation valves range in size from 1 inch to 3 inches; piping valves range in size from 1 inch to 24 inches. API 3.000 to API 10.000 in all pressure class scores from 150 to 2500 lbs.

Integral DBB Valves – These valves are used in the instrumentation industry and come in a variety of designs to meet a variety of needs, including flange to flange, flange to the thread, injection, and sampling, and ball and needle types. A drain needle valve is located between the two balls on the Integral Double Block and Bleed valve. This allows the valve to be drained and the pressure to be reset to zero.

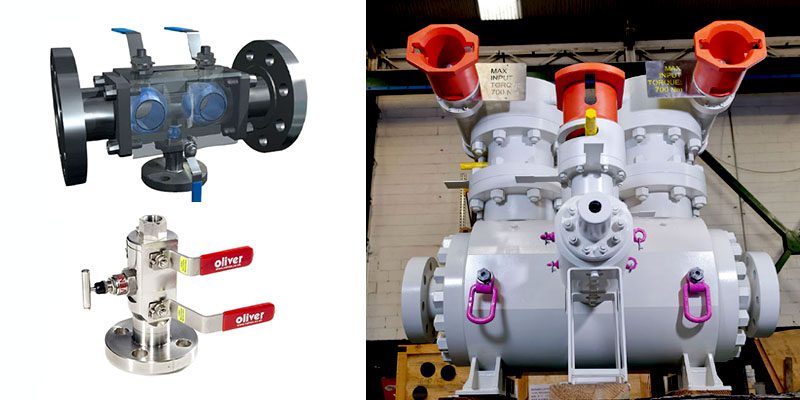

Dual Expanding Plug Valves – These valves are easy to operate, require very little maintenance and offer verifiable double block and bleed service with an extraordinarily long lifetime. Not only do they avoid product loss, but our valves also prevent fuel contamination in Multi- Product-Manifolds, avoid errors in metre calibration and at the same time help to protect health and the environment by positively containing the fluid in the pipeline.

Installing Double Block and Bleed Valves can be trickier than other, simpler types of valves. Because it can be quite complex, it’s best to consult a valve expert or look at training options for your valve installation.

You can also contact our trainer directly as per below contact details

e: Iain@winnellievalves.com

ph: +61 (0) 417 279 508