At Winnellie Valve and Process, we supply quality Cryogenic Valves in a range of design types to suit all applications. If you’re looking to buy Cryogenic Valves online in Australia, you need look no further than our extensive product range. If you’re unsure about which type of Cryogenic Valve you need for your application, or would simply like more information and guidance, Winnellie Valve and Process are only too happy to chat through your options with you.

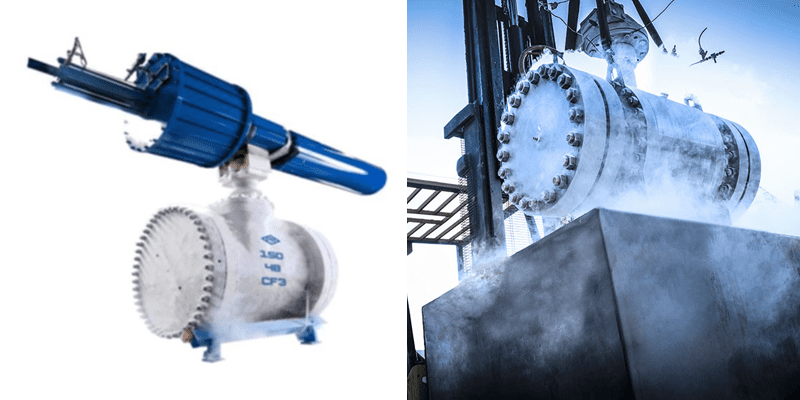

As the namesake implies, Cryogenic Valves deal with low-temperature mediums such as liquid hydrogen, liquid oxygen, liquefied natural gas (LNG), helium and ethylene – applications commonly seen in the oil and gas industry. Because they deal with mediums and processes that operate below -150 degrees Celsius the valves themselves need to be designed with properties that can handle such low temperatures.

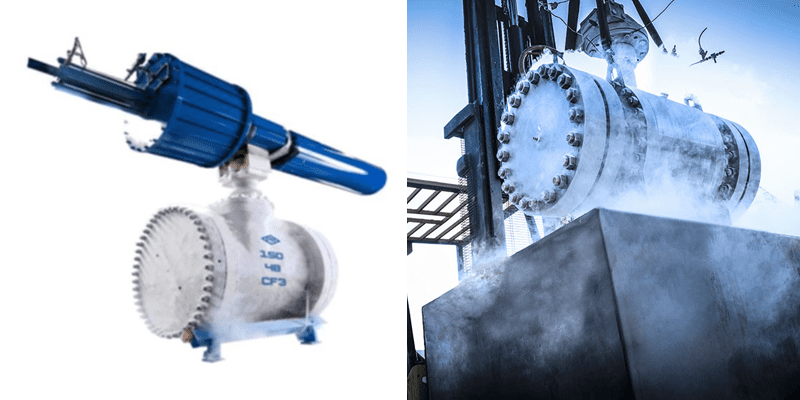

Cryogenic Valves are easily identifiable externally as they have a much longer stem than a normal valve to extend the distance between the packing material and the cold product.

Typical designs of Cryogenic Valves include:

Do you require assistance to buy the right Cryogenic Valves for your business? Contact a Winnellie Valves and Process valve expert today so they can help guide you to choosing the right valve for your application. Did you know that we also provide training on valve and process applications? Find out more about our training services.

Utilised in extremely cold applications, Cryogenic Valves are often used in liquefied gaseous applications such as liquefied natural gas and compressed natural gas, as well as in chemical processes for materials such as liquid nitrogen. If you are unsure if a Cryogenic Valve is right for you, contact a valve expert today.

Cryogenic Valves are made from high-grade materials that are purpose-built to withstand low temperatures and are typically made from modified austenitic stainless steel that contains a higher percentage of nickel. That being said, the longevity of the Cryogenic Valve will be dependent on the type of media used in the application and the frequency of its use. To know more about how long you can expect your valves to last for your application, contact one of our valve and process experts.

There are a few different types and sizes of Cryogenic Valves available so it’s best to get in touch with a valve specialist so you can ensure you are getting the right product for your application. For more information on what type of Cryogenic Valve you require and tips on how to maintain your valves, contact a Winnellie Valves and Process expert today.

You can also contact our trainer directly as per below contact details

e: Iain@winnellievalves.com

ph: +61 (0) 417 279 508