At Winnellie Valve and Process, we supply quality Strainers and Filtersin a range of design types to suit all applications. If you’re looking to buy Strainers and Filters in Australia, you need look no further than our extensive product range. If you’re unsure about which type of Strainers and Filtersyou need for your application, or would simply like more information and guidance, Winnellie Valve and Process are only too happy to chat through your options with you.

For heavy industrial applications Strainers (or Filters) are commonly used to capture solid particles and solid contaminants within liquids or gases to stop them from continuing through a system.

When functioning properly, Strainers are able to prevent potential damage to other parts of the system, including:

They are an integral part of a process systems to remove large contaminants and come in 4 common varieties as:

Simplex strainers are commonly used in oil and gas processes – a basket-type strainer that is kept permanent in its application. The strainer can be made out of a variety ofmaterials; usually iron, steel or stainless steel. The basket/filter element is available with a number of different filtration grades.

Y Strainers are known for their “Y” shape, which is designed to mechanically remove unwanted solids from liquids, gasses and steam lines via a perforated wire mesh straining implement. They are often used in pipelines to protect valves, pumps, meters, steam traps, regulators and other process equipment.

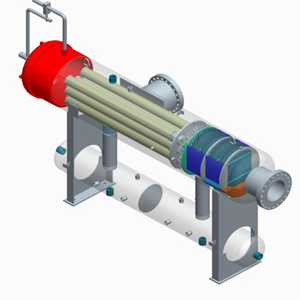

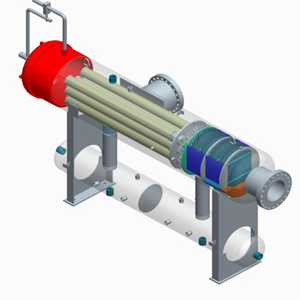

Duplex Strainers are renowned for being easy to maintain. They are designed to be easily opened and are able to be cleaned individually while the other strainer is on standby. Duplex Strainers have a high-particle holding capacity for less pressure drop through the strainer.

These types of strainers are almost self-explanatory. Automatic Strainers are self-cleaning and sit permanent, so the cleaning process does not interrupt the process. The self-cleaning modules can be controlled via timers, pressure drop settings or manual control. These strainers are commonly made from iron, steel and stainless steel.

There are also T-Type Strainers, Conical Strainers, Temporary and Suction Strainers which are specific to certain applications. Contact a Winnellie Valve and Process expert to see which one is suitable for your needs.

Strainers and Filters are used in a wide range of industrial applications such as:

No matter whether you are trying to prevent debris going into your pumps or remove condensate from a gas pipeline, Winnellie Valve and Process has the right strainer/filter for the application.

In partnership with industry-leading OEM’s we have the engineering capabilities to design and manufacture filters to suit your application based on the process data provided. Using only Australian vessel manufacturers, we ensure all products meet the relevant standards and are of the highest quality no matter what the pressure rating, material or application.

To get the right Strainers or Filters for your application contact one of our valve experts today.

It’s always best to have a qualified technician install your process equipment for industrial applications. However, if you want to be able to install Strainers and Filters yourself, contact a valve expert to guide you through the process. Winnellie Valves and Process also provide valve training courses for all types of valve and process equipment.

You can also contact our trainer directly as per below contact details

e: Iain@winnellievalves.com

ph: +61 (0) 417 279 508